Lub polisher, tseem hu ua lub tshuab polishing lossis tsis, yog lub zog siv los txhim kho qhov pom ntawm qhov chaw los ntawm kev tshem tawm qhov tsis zoo, khawb, lossis dullness thiab tsim kom zoo nkauj thiab zoo nkauj.Nws yog feem ntau siv hauv kev nthuav dav tsheb, kev ua haujlwm ntoo, hlau ua haujlwm, thiab lwm yam lag luam uas xav tau kev ua tiav zoo.

Composition ibPolisher

Cov muaj pes tsawg leeg ntawm polisher tuaj yeem sib txawv nyob ntawm cov khoom tshwj xeeb thiab nws qhov kev siv.Txawm li cas los xij, muaj qee qhov sib xyaw thiab cov khoom xyaw uas feem ntau pom hauv polishers.Nov yog ob peb yam tseem ceeb:

Abrasives:

Polishers feem ntau muaj cov khoom siv abrasive uas pab tshem tawm qhov tsis zoo thiab tsim kom zoo nkauj.Cov abrasives no tuaj yeem ua rau hauv daim ntawv los yog cov khoom sib txuas, xws li txhuas oxide, silicon carbide, lossis pob zeb diamond plua plav.Hom thiab qhov loj ntawm cov abrasive siv tuaj yeem sib txawv raws li qib polishing xav tau thiab cov khoom siv polished.

Binders:

Binders yog cov khoom uas tuav cov khoom abrasive ua ke thiab pab lawv ua raws li polishing ncoo los yog disc.Cov binders feem ntau suav nrog cov resins lossis polymers uas muab kev sib koom ua ke thiab ruaj khov rau cov khoom siv abrasive.

Lubricants:

Lubricants yog siv nyob rau hauv polishers los txo kev sib txhuam thiab tshav kub generated thaum lub sij hawm polishing txheej txheem.Lawv pab tiv thaiv lub polishing ncoo los yog disc los ntawm overheating thiab txo qhov kev pheej hmoo ntawm kev puas tsuaj rau saum npoo polished.Lubricants tuaj yeem ua cov roj, waxes, lossis dej-raws li kev daws teeb meem.

Cov kuab tshuaj:

Qee cov polishers yuav muaj cov kuab tshuaj uas pab kom yaj lossis tawg qee yam tshuaj, xws li roj, roj, lossis cov khoom paug ntawm qhov chaw polished.Cov kuab tshuaj tuaj yeem pab tu thiab npaj ntawm qhov chaw ua ntej polishing.

Additives:

Polishers kuj tseem muaj ntau yam ntxiv los txhim kho lawv cov kev ua tau zoo lossis muab cov khoom tshwj xeeb.Cov tshuaj ntxiv no tuaj yeem suav nrog surfactants los txhim kho kev sib kis thiab ntub dej, cov tshuaj tiv thaiv zoo li qub los txo cov hluav taws xob zoo li qub, lossis cov tshuaj tiv thaiv corrosion los tiv thaiv cov hlau.

Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias muaj pes tsawg leeg ntawm polishers tuaj yeem sib txawv heev nyob ntawm cov khoom tshwj xeeb thiab nws qhov kev npaj siv.Ntau hom polishers, xws li siv rau kev nthuav dav tsheb, kev ua haujlwm ntoo, lossis hlau polishing, tej zaum yuav muaj cov qauv tsim tshwj xeeb raws li cov kev xav tau ntawm cov ntawv thov.

Thaum siv polishers, nws yog ib qho tseem ceeb uas yuav tsum tau ua tib zoo nyeem thiab ua raws li cov chaw tsim khoom cov lus qhia thiab cov txheej txheem kev nyab xeeb kom ntseeg tau tias siv tau thiab ua tiav cov txiaj ntsig xav tau.

Keeb kwm ntawm polishers

Keeb kwm ntawm polishers yog ib qho kev taug kev zoo nkauj uas nthuav dav ntau yam kev lag luam thiab qhia txog kev nce qib hauv cov ntaub ntawv, thev naus laus zis, thiab kev ua haujlwm zoo nkauj.Los ntawm kev pib txo qis mus rau cov cuab yeej ntse, cia peb delve rau hauv ncua sij hawm ntawm cov polishers tau hloov zuj zus ntau xyoo:

Early pib:

Tes Rubbing:

- Ua ntej qhov kev tsim kho ntawm cov tshuab polishers, ua tiav polished tiav yog nyob ntawm kev siv dag zog.Craftsmen siv cov ntaub ntawv zoo li cov hmoov abrasive thiab cov ntaub los ntawm tes txhuam, cov txheej txheem ua haujlwm hnyav uas yuav tsum tau muaj kev txawj ntse thiab ua siab ntev.

20 xyoo pua:

Taw qhia ntawm Electric Polishers:

- Nrog rau qhov tshwm sim ntawm hluav taws xob, lub xyoo pua 20th thaum ntxov tau pom qhov tshwm sim ntawm hluav taws xob polishers.Cov khoom siv no muaj cov txhuam txhuam los yog cov ntaub qhwv uas siv los ntawm lub tshuab hluav taws xob, txo cov kev siv zog ntawm phau ntawv yuav tsum tau ua rau polishing.

Automotive Industry Txais:

- Hluav taws xob polishers pom kev lees paub sai hauv kev lag luam tsheb rau kev nthuav dav thiab kho xim.Lub sijhawm no pom qhov yug ntawm cov tsheb tshwj xeeb polishers tsim los txhim kho qhov zoo nkauj ntawm lub tsheb tiav.

Thaum xaus ntawm lub xyoo pua 20th:

Kev nce qib hauv Orbital Motion:

- Lub xyoo pua 20th lig coj kev tsim kho tshiab hauv orbital motion technology.Orbital polishers, tus cwj pwm los ntawm lawv cov voj voog thiab oscillating txav, tau txais koob meej vim lawv cov neeg siv khoom tsim thiab ua haujlwm zoo hauv kev tiv thaiv cov cim swirl.

Dual-Action (DA) Polishers:

- Dual-action polishers, combining orbital thiab rotary txav, tau tshwm sim los daws qhov kev pheej hmoo ntawm holograms lossis swirls tshwm sim los ntawm cov tsoos rotary polishers.DA polishers tau siv dav rau kev nthuav dav tsheb thiab lwm yam haujlwm zoo polishing.

21st caug xyoo:

Kev koom ua ke thev naus laus zis:

- Lub xyoo pua 21st tau pom txog kev sib koom ua ke ntawm cov thev naus laus zis siab heev rau hauv polishers.Kev sib hloov ceev ceev, tsim ergonomic, thiab digital tswj tau dhau los ua cov qauv zoo, txhim kho cov neeg siv kev tswj hwm thiab kev ua haujlwm zoo.

Tshwj xeeb Polishers:

- Qhov kev thov rau cov polishers tshwj xeeb tau loj hlob thoob plaws kev lag luam.Los ntawm cov hlau polishing mus rau woodworking thiab txawm tias hluav taws xob cov cuab yeej polishing, manufacturers tsim polishers haum rau cov ntaub ntawv tshwj xeeb thiab kev siv.

Cordless Polishers:

- Cordless polishers, powered los ntawm rechargeable roj teeb, tau muaj koob meej, muab nce mus thiab yooj yim.Qhov kev txhim kho no tau hloov pauv cov neeg siv kev paub dhau los, tshwj xeeb tshaj yog nyob rau hauv kev nthuav dav tsheb qhov twg maneuverability tseem ceeb heev.

Hnub Nyoog Kawg:

Txuas ntxiv Innovation:

- Nruam kev tsim kho tshiab hauv cov ntaub ntawv, lub cev muaj zog thev naus laus zis, thiab polishing compounds ua kom cov polishers niaj hnub xa cov txiaj ntsig zoo nrog qhov tseeb thiab nrawm.Kev ua lag luam muaj ntau hom polishers catering rau cov kws tshaj lij thiab cov neeg nyiam ua haujlwm zoo ib yam.

Los ntawm phau ntawv qhia kev siv zog ntawm cov kws ua haujlwm rau cov khoom siv hluav taws xob thiab cov khoom siv tsis muaj zog niaj hnub no, kev hloov pauv ntawm polishers qhia txog kev cog lus kom ua tiav kev ua tiav tsis tiav thoob plaws ntau qhov chaw.Txawm hais tias siv hauv kev nthuav dav tsheb, kev ua haujlwm ntoo, lossis kev siv ua lag luam, polishers txuas ntxiv ua lub luag haujlwm tseem ceeb hauv kev txhim kho kev zoo nkauj ntawm cov khoom sib txawv.

Hom Polishers

A. Orbital Polishers:

- Mechanism:Cov polishers no txav mus rau hauv ib qho orbital motion, oscillating nyob rau hauv ib lub voj voog.Lawv yog cov neeg siv-phooj ywg, ua rau lawv haum rau cov pib tshiab thiab cov haujlwm polishing dav dav.

- Cov ntawv thov:Zoo tagnrho rau lub teeb rau nruab nrab polishing, feem ntau siv rau kev nthuav dav tsheb thiab rooj tog tej yaam num.

B.Rotary Polishers:

- Mechanism: Rotary polishers muaj kev sib hloov ncaj qha thiab ruaj khov, muab lub peev xwm polishing muaj zog.Lawv feem ntau nyiam los ntawm cov kws tshaj lij vim lawv qhov ua tau zoo.

- Daim ntawv thov: Haum rau kev ua haujlwm hnyav, xws li tshem tawm cov khawb tob los ntawm cov xim tsheb lossis kho cov huab cua hnyav heev.

C.Dual-Action (DA) Polishers:

- Mechanism: DA polishers muab ob qho tib si teb thiab orbital txav, muab versatility thiab txo qhov kev pheej hmoo ntawm swirl marks lossis holograms.

- Daim ntawv thov: Feem ntau siv rau kev nthuav dav tsheb, cov polishers no muab cov txiaj ntsig zoo nrog txo kev pheej hmoo ntawm cov xim puas.

Yuav ua li cas Polishers ua haujlwm

Polishers yog cov cuab yeej tseem ceeb hauv kev ua tiav qhov ua tiav tsis tiav ntawm ntau qhov chaw.Cia peb delve rau hauv intricacies ntawm lawv cov hauj lwm, tshawb txog peb lub ntsiab mechanisms: teb motion, dual-action, thiab orbital txav.

A. Rotary Motion Explanation

Rotary polishers, tseem hu ua ncig polishers, ua haujlwm ntawm lub hauv paus ntsiab lus ncaj nraim ntawm kev sib tw hauv kev ncig.Cov lus tsa suab yog tus cwj pwm los ntawm lub ncoo qhov kev txav mus tas li, zoo li lub laum lossis lub cuab yeej sib tsoo.Cov ntsiab lus tseem ceeb kom nkag siab txog rotary polishers suav nrog:

1. Kev sib hloov ceev:

- Rotary polishers paub txog lawv qhov kev sib hloov ceev, ua rau lawv muaj txiaj ntsig zoo hauv kev tshem tawm cov teeb meem hnyav xws li khawb thiab cov cim swirl.

- Lub zog spinning generates cua sov, yuav tsum tau ceev faj tswj kom tsis txhob muaj kev puas tsuaj rau cov xim los yog nto.

2.Professional-Qib Polishing:

Qhov zoo tshaj plaws rau cov kws tshaj lij lossis cov neeg siv paub txog vim muaj kev pheej hmoo ntawm kev hlawv cov xim yog tias tsis ua haujlwm nrog kev saib xyuas.

Haum rau cov haujlwm uas xav tau kev kho cov xim nruj.

B.Dual-Action Mechanism

Dual-action polishers, tseem hu ua random orbital polishers, muab ob qho tib si spinning thiab oscillating motion.Qhov kev ua haujlwm ob npaug no muab kev nyab xeeb dua thiab siv tau yooj yim dua rau kev polishing.Cov yam ntxwv tseem ceeb ntawm dual-action polishers muaj xws li:

1. Simultaneous Spinning thiab Oscillation:

Dual-action polishers simulate tes polishing tab sis nrog kev ua haujlwm ntawm lub tshuab.

Lub ncoo tsis tsuas yog tig tab sis kuj txav mus rau hauv cov lus tsa suab oscillating, txo qhov kev pheej hmoo ntawm kev kub ntxhov thiab xim puas.

2.Safe rau Beginners:

Dual-action polishers yog cov neeg pib tshiab, ua rau lawv yog qhov kev xaiv zoo tshaj plaws rau cov neeg nyiam ua tshiab rau tshuab polishing.

Lawv tsis tshua muaj peev xwm ua rau cov xim kub hnyiab los yog swirl marks, muab kev zam txim rau polishing kev.

C.Orbital Movement Details

Orbital polishers, qee zaum hu ua random orbit polishers, suav nrog qhov sib txawv txav uas ua rau lawv sib nrug ntawm lwm hom.Nkag siab txog kev txav ntawm lub orbital yuav tsum nkag siab cov ntsiab lus hauv qab no:

1. Circular thiab Eccentric Movement:

Orbital polishers muab cov lus tsa suab ncig nrog lub voj voog eccentric.

Lub eccentric orbit xyuas kom meej tias lub ncoo txav mus rau hauv ntau yam qauv, txo qhov kev pheej hmoo ntawm holograms los yog swirl marks.

2.Yooj yim tab sis siv tau polishing:

Orbital polishers tawm tsam qhov sib npaug ntawm lub zog ntawm cov polishers rotary thiab kev nyab xeeb ntawm dual-action polishers.

Lawv tsim nyog rau ntau yam haujlwm, muab cov xim kho kom zoo nrog kev pheej hmoo ntawm kev puas tsuaj.

Hauv kev xaus, qhov ua tau zoo ntawm polishers nyob hauv lawv lub peev xwm los ua kom tau raws li cov kev xav tau tshwj xeeb.Rotary polishers xa cov txiaj ntsig zoo tshaj plaws tab sis xav tau kev tshaj lij, thaum ob qho kev ua thiab orbital polishers muab kev nyab xeeb rau ob qho tib si pib thiab cov neeg siv paub txog.Nkag siab txog cov txheej txheem no txhawb cov neeg siv los xaiv txoj cai polisher rau lawv cov hom phiaj polishing tshwj xeeb.

Feem ntau siv Polishers

Polishers yog ntau yam cuab yeej uas nrhiav tau daim ntawv thov nyob rau hauv ntau yam kev lag luam, txhim khu cov tsos thiab smoothness ntawm txawv qhov chaw.Nov yog qee qhov kev siv ntawm polishers:

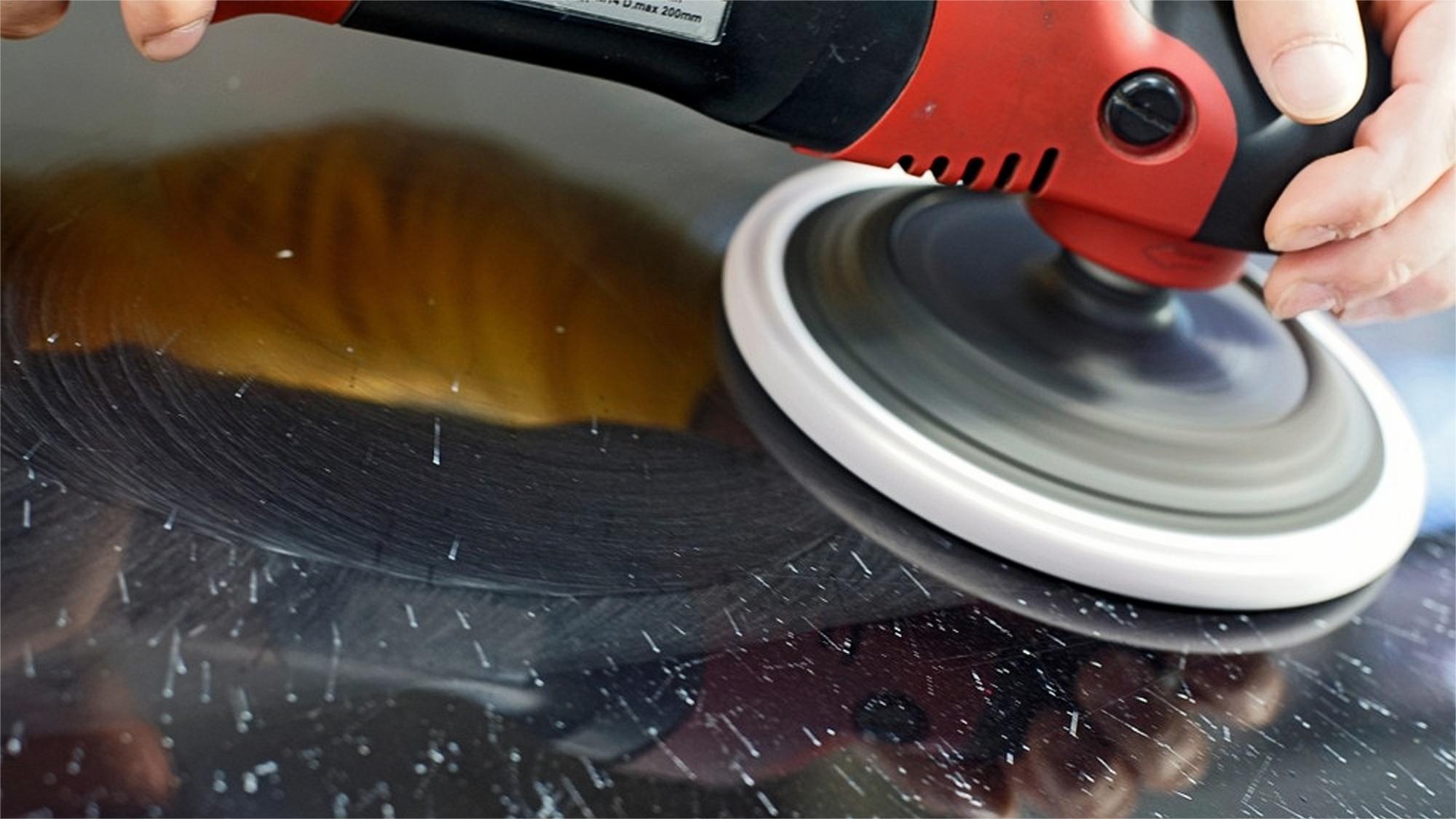

A. Automotive Detailing:

Polishers ua lub luag haujlwm tseem ceeb hauv kev nthuav dav tsheb, qhov uas ua tiav qhov tsis zoo thiab glossy tiav yog qhov tseem ceeb.Lawv yog siv los tshem tawm khawb, swirl marks, thiab oxidation los ntawm lub tsheb xim, kho lub tsheb lub ci thiab luster.

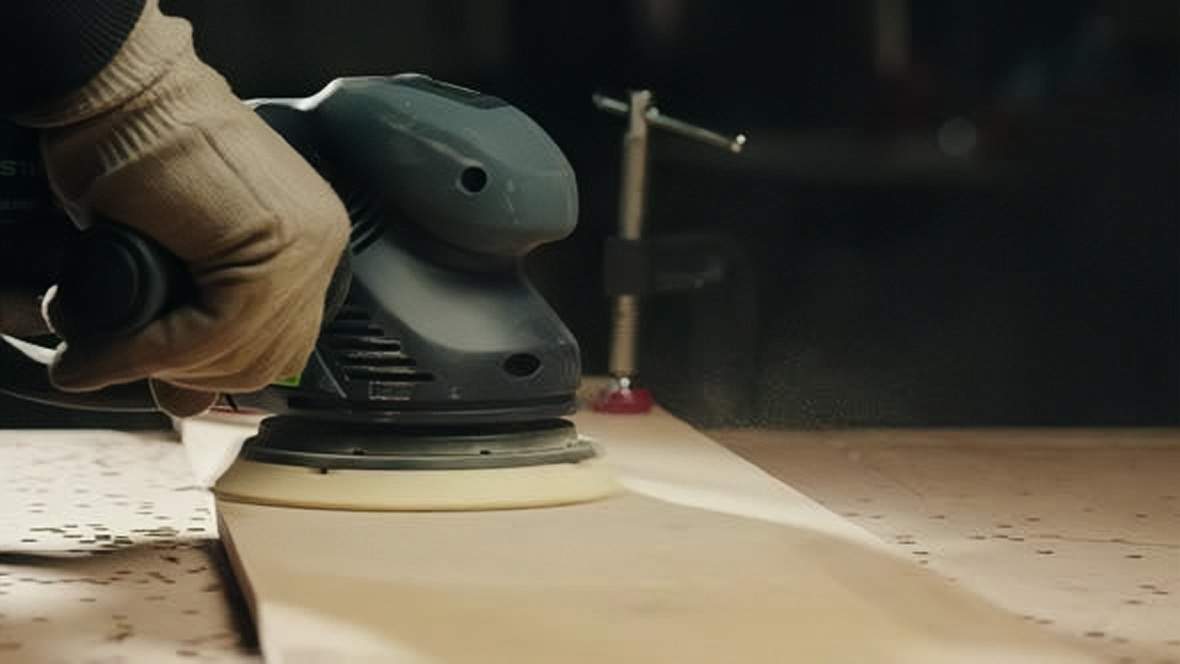

B.Woodworking:

Hauv kev ua haujlwm ntoo, polishers pab txhawb kom ua tiav kev sib tw thiab polished tiav ntawm cov ntoo.Txawm hais tias ua khoom siv rooj tog, txee, lossis cov khoom siv ntoo zoo nkauj, polishers pab coj tawm qhov zoo nkauj ntawm cov ntoo.

C.Hlau Polishing:

Hlau nto tau txais txiaj ntsig los ntawm polishing kom tshem tawm tarnish, khawb, lossis oxidation.Polishers tau ua haujlwm los kho qhov ci thiab du ntawm cov hlau zoo li chrome thiab stainless hlau, txhim kho lawv qhov zoo nkauj.

D.Marble thiab pob zeb nto:

Polishers yog siv dav hauv kev saib xyuas ntawm marble thiab pob zeb nto.Txawm hais tias rau countertops, pem teb, lossis cov pob zeb zoo nkauj, polishers coj tawm lub ntuj lus ntawm cov ntaub ntawv no, tsim kom zoo nkauj thiab zoo nkauj.

E.DIY Projects:

Cov neeg txhawb siab koom nrog ua-nws-koj tus kheej (DIY) cov phiaj xwm leverage polishers rau ntau yam dej num.Los ntawm kev kho cov xim faded ntawm cov khoom hauv tsev mus rau polishing hlau fixtures, DIYers siv polishers los txhim kho qhov pom kev pom ntawm lawv cov haujlwm.

Lub versatility ntawm polishers txuas ntxiv tshaj cov kev siv no, nrhiav kev siv nyob rau hauv ntau yam lag luam thiab tej yaam num.Txawm hais tias koj yog tus kws tshaj lij craftsman, automotive enthusiast, los yog ib tug tswv tsev nrog ib tug mob siab rau DIY, ib tug zoo polisher yog ib tug invaluable cuab tam rau ua tiav impeccable finishes thiab txhim kho tag nrho cov aesthetic ntawm qhov chaw.

Cov lus qhia kom zoo polishing

Ua kom tiav ib qho zoo meej polish muaj ntau dua li siv cov cuab yeej zoo.Nov yog cov lus qhia tseem ceeb los xyuas kom koj cov kev siv zog polishing tau txais txiaj ntsig zoo:

A. Xaiv txoj cai Polish:

Xaiv cov polish tsim nyog rau cov khoom koj tab tom ua haujlwm yog qhov tseem ceeb heev.Cov chaw sib txawv yuav tsum muaj cov qauv tsim tshwj xeeb, yog li xyuas kom koj siv polish haum rau txoj haujlwm ntawm tes.Txawm hais tias nws yog automotive xim, ntoo, lossis hlau, txoj cai polish txhim khu kev ua tau zoo thiab ua kom muaj polished tiav.

B.Pib nrog Clean Surface:

Ua ntej koj pib polishing, xyuas kom meej tias qhov chaw tsis muaj av, plua plav, lossis khib nyiab.Kev ntxuav thaj tsam ua ntej tiv thaiv khawb thiab ua kom cov txheej txheem polishing smoother.Tshem tawm tej yam kab mob kom ua tiav qhov zoo tshaj plaws.

C.Siv cov txheej txheem kom raug:

Txhua hom polisher yuav tsum muaj cov txheej txheem tshwj xeeb rau cov txiaj ntsig zoo.Txawm hais tias koj siv lub orbital, rotary, lossis dual-action polisher, ua raws li cov txheej txheem pom zoo.Siv cov lus tsa suab thiab cov kaum sab xis kom ua tau zoo polishing yam tsis muaj kev puas tsuaj rau saum npoo.

D.Thov Txawm Siab:

Lub siab sib xws yog qhov tseem ceeb rau kev ua tiav cov txiaj ntsig sib xws.Siv txawm tias siab thoob plaws tag nrho saum npoo koj polishing.Qhov no xyuas kom meej tias cov polish yog faib sib npaug, tiv thaiv tsis sib xws polishing thiab muaj peev xwm puas tsuaj rau cov khoom.

Los ntawm kev ua raws li cov lus qhia no, koj yuav txhim khu kev ua tau zoo ntawm koj cov kev siv zog polishing, txawm tias koj ua haujlwm ntawm koj lub tsheb, cov haujlwm ua haujlwm ntoo, lossis lwm qhov chaw uas xav tau polished tiav.Nco ntsoov, txoj cai polishing, qhov chaw huv si, cov txheej txheem tsim nyog, thiab txawm tias lub siab yog cov ncej ntawm kev ua tiav thiab tsis muaj qhov tsis zoo.

Features xav txog thaum twgXaiv ib tug Polisher

Xaiv txoj cai polisher yog qhov tseem ceeb rau kev ua tiav cov txiaj ntsig zoo hauv koj cov haujlwm polishing.Nov yog cov yam ntxwv tseem ceeb los txiav txim siab thaum txiav txim siab:

A. Fais fab thiab ceev chaw:

Nrhiav ib tug polisher nrog adjustable zog thiab ceev chaw.Cov ntaub ntawv sib txawv thiab cov dej num yuav xav tau ntau theem ntawm lub zog.Muaj kev tswj xyuas qhov nrawm tso cai rau kev ua kom zoo hauv polishing thiab tiv thaiv kev puas tsuaj rau qhov chaw rhiab.

B.Pad Loj thiab Hom:

Xav txog qhov loj ntawm polishing ncoo thiab hom ncoo nws los nrog.Cov ntaub ntawv loj dua npog thaj tsam ntau dua, ua rau lawv tsim nyog rau cov haujlwm loj dua, thaum cov ntaub me me muab qhov tseeb dua.Cov ntaub ntawv sib txawv yog tsim los rau cov haujlwm tshwj xeeb, xws li txiav, polishing, lossis ua tiav.

C.Variable Speed Control:

Lub polisher nrog kev sib txawv ntawm kev ceev tswj tau yooj yim rau kev siv sib txawv.Muaj peev xwm kho qhov nrawm tso cai rau koj los kho cov txheej txheem polishing rau cov kev cai tshwj xeeb ntawm cov khoom koj ua haujlwm.

D.Ergonomic Tsim:

Xaiv lub polisher nrog ergonomic tsim rau kev nplij siab thaum siv txuas ntxiv.Saib rau cov yam ntxwv xws li tuav tau yooj yim, sib npaug ntawm qhov hnyav, thiab kev tswj tau yooj yim.Tus tsim ergonomic txo cov neeg siv qaug zog thiab txhim kho kev tswj tag nrho.

E.Corded vs Cordless:

Xav txog seb koj puas xav tau ib lub corded lossis cordless polisher.Corded qauv muab lub zog tas li tab sis tuaj yeem txwv kev txav mus los.Cordless qauv muab kev yooj yim dua tab sis xav tau kev tswj roj teeb.Xaiv raws li koj qhov kev xav tau tshwj xeeb thiab qhov yooj yim ntawm kev txav mus los.

F.Ua kom zoo thiab kav ntev:

Ua lag luam nyob rau hauv ib tug polisher nrog ib tug robust tsim zoo los xyuas kom meej lub neej ntev thiab durability.Cov ntaub ntawv zoo thiab kev tsim kho ua rau lub cuab yeej ua tau zoo thiab lub neej ntev.

G.Yooj yim ntawm Pad Hloov:

Nrhiav ib tug polisher nrog ib tug ceev thiab yooj yim ncoo-hloov mechanism.Qhov no feature streamlines tus txheej txheem ntawm kev hloov ntawm txawv polishing hauj lwm, txuag lub sij hawm thiab kev rau siab nyob rau hauv koj tej yaam num.

H.Kev nyab xeeb nta:

Ua ntej polishers nrog kev ruaj ntseg nta xws li kev tiv thaiv overload, uas tiv thaiv overheating, thiab kev ruaj ntseg rau / tawm mus.Kev nyab xeeb yuav tsum nco ntsoov yog qhov tseem ceeb tshaj plaws thaum ua haujlwm nrog cov cuab yeej hluav taws xob.

I.Brand Reputation thiab Reviews:

Tshawb nrhiav lub koob npe nrov ntawm lub hom thiab nyeem cov neeg siv tshuaj xyuas los ntsuas qhov kev ntseeg tau thiab kev ua haujlwm ntawm polisher.Lub npe nrov npe nrog kev tshuaj xyuas zoo yog qhov yuav muab cov khoom lag luam zoo.

Xav txog cov yam ntxwv no yuav coj koj xaiv txoj cai polisher rau koj cov kev xav tau tshwj xeeb, txawm tias koj koom nrog kev nthuav dav tsheb, kev ua haujlwm ntoo, lossis lwm qhov project polishing.

Step-by-Step Guide to Polishing

Polishing yog cov txheej txheem hloov pauv uas txhim kho qhov pom ntawm qhov chaw.Ntawm no yog cov lus qhia ua ntu zus los ua kom tiav qhov tsis muaj qhov kawg:

A. Kev Npaj ntawm Qhov Nto

1. Ntxuav lub ntsej muag kom huv si:

- Pib los ntawm kev ntxuav qhov chaw kom tshem tawm cov av, grime, lossis kab mob.

- Siv lub tsheb maj mam los yog lub tshuab ntxhua khaub ncaws kom paub meej qhov pib huv.

2.Tshawb nrhiav qhov tsis zoo:

- Ua tib zoo tshuaj xyuas qhov chaw rau khawb, swirl marks, lossis lwm yam tsis zoo.

- Txheeb xyuas thaj chaw uas xav tau kev saib xyuas tshwj xeeb thaum lub sijhawm polishing.

3.Mask Off Sensitive Areas:

- Tiv thaiv qhov chaw nyob ib sab, trims, lossis thaj chaw uas muaj kev puas tsuaj los ntawm kev npog lawv nrog cov neeg pleev kob daim kab xev.

- Ua kom pom tseeb qhov chaw ua haujlwm kom tsis txhob muaj kev puas tsuaj thaum lub sijhawm polishing.

4.Clay Bar Treatment (yeem):

- Xav txog kev siv cov av nplaum kom tshem tawm cov kab mob sib kis los ntawm qhov chaw.

- Khiav cov av nplaum maj mam hla saum npoo kom ua tiav lub hauv paus du rau polishing.

B.Xaiv txoj cai Polish

1. Txheeb xyuas hom xim:

- Txiav txim siab seb qhov chaw puas muaj ib-theem lossis cov xim ntshiab-coated.

- Cov xim sib txawv tuaj yeem xav tau hom polish.

2.Xaiv qhov tsim nyog Abrasiveness:

- Xaiv lub polish nrog rau qib zoo ntawm abrasiveness raws li qhov hnyav ntawm qhov tsis zoo.

- Tsawg abrasive polishes yog tsim rau me me tsis xws luag, thaum ntau abrasive sawv daws yuav ntxaum khawb.

3.Xav txog kev ua tiav polishing:

- Rau qhov chaw uas muaj qhov tsis zoo me me los yog cov neeg nyob hauv qhov zoo, xaiv qhov polishing polishing los txhim kho gloss thiab ci.

-Txoj polishes tsis tshua muaj abrasive thiab ua rau lub ntsej muag zoo nkauj.

4.Kev sim hauv ib cheeb tsam me me:

- Ua ntej daim ntawv thov tag nrho, sim cov polish xaiv hauv thaj chaw me me, tsis pom tseeb.

- Qhov no tso cai rau koj los ntsuas nws cov txiaj ntsig yam tsis muaj kev cog lus rau tag nrho saum npoo.

C.Cov txheej txheem tsim nyog rau polishing

1. Siv Polish:

- Siv cov npuas dej los yog microfiber applicator ncoo los siv cov txhuam me me rau ntawm qhov chaw.

- Pib nrog tus nqi me me thiab ntxiv ntxiv yog tias xav tau.

2.Siv Txoj Cai Polishing Tool:

- Xaiv cov cuab yeej polishing uas tsim nyog - teb, ob qho kev ua, lossis orbital - raws li koj qib kev txawj ntse thiab txoj haujlwm ntawm tes.

- Xyuas kom lub cuab yeej nyob rau hauv zoo, thiab polishing ncoo yog huv si thiab haum rau cov xaiv polish.

3.Polishing Motion:

- Ua haujlwm hauv ntu, siv cov txhuam hauv sib tshooj, cov kab ncaj.

- Kho lub siab thiab ceev ntawm cov cuab yeej polishing raws li qib kev kho yuav tsum tau ua.

4.Saib xyuas kev nce qib:

- Tsis tu ncua tshuaj xyuas thaj tsam polished los ntsuas qhov kev nce qib.

- So kom huv si nrog cov phuam microfiber huv si los ntsuas qhov tseeb ntawm qhov chaw.

5.Rov ua dua raws li xav tau:

- Yog tias tsim nyog, rov ua cov txheej txheem polishing kom txog thaum qhov kev xav tau ntawm kev kho tiav tiav.

- Nco ntsoov tsis txhob polished, tshwj xeeb tshaj yog nyob rau ntawm qhov chaw ntshiab-coated.

6.Kev soj ntsuam zaum kawg:

- Thaum txaus siab rau cov txiaj ntsig, ua tib zoo tshuaj xyuas tag nrho polished nto.

- Tshem tawm cov kua nplaum uas seem tshuav nrog cov ntaub so huv, qhuav microfiber phuam.

7.Siv lub sealant los yog siv quav ciab (xaiv tau):

- Xav txog kev siv cov tshuaj tiv thaiv los yog siv quav ciab los txhim kho thiab khaws cov polished tiav.

- Ua raws li cov lus qhia khoom rau kev thov kom raug.

Los ntawm kev ua raws li cov lus qhia ib kauj ruam dhau los no, koj tuaj yeem ua tus kos duab ntawm polishing, hloov qhov chaw thiab ua tiav qhov zoo nkauj, zoo nkauj.

Cov txiaj ntsig ntawm kev siv Polisher

Polishers yog cov cuab yeej tseem ceeb hauv lub ntiaj teb ntawm kev saib xyuas saum npoo, muab ntau yam txiaj ntsig uas mus dhau qhov zoo nkauj.Ntawm no yog ib qho kev tawg ntawm cov txiaj ntsig tseem ceeb ntawm kev sib koom ua tus polisher rau hauv koj qhov kev tu ncua sij hawm:

A. Ua tiav Kev Ua Haujlwm tiav

1. Flawless Surface Kho:

Polishers ua tau zoo hauv kev kho qhov tsis zoo xws li cov cim swirl, khawb, thiab oxidation, xa ib theem ntawm kev kho uas nyuaj kom ua tiav ntawm tes.

2.Enhanced Gloss thiab ci:

Lub tshuab ua haujlwm ntawm polisher, ua ke nrog txoj cai polishing tebchaw, txhim khu lub gloss thiab ci ntawm qhov chaw, muab cov qib kev ua tiav.

3.Cov txiaj ntsig sib xws:

Polishers xyuas kom meej daim ntawv thov thiab kev faib tawm ntawm polishing tebchaw, ua rau cov txiaj ntsig zoo ib yam thiab txhim khu kev qha thoob plaws txhua qhov chaw.

B.Lub Sijhawm thiab Kev Siv Zog Txuag

1. Kev Kho Kom Zoo:

Piv nrog rau cov txheej txheem ntawm phau ntawv, polishers txo cov sij hawm thiab kev siv zog uas yuav tsum tau rau kev kho qhov chaw, ua rau lawv zoo tagnrho rau cov haujlwm loj.

2.Kev siv tus phooj ywg zoo:

Cov polishers niaj hnub, tshwj xeeb tshaj yog ob qho kev ua thiab cov qauv orbital, yog tsim los ua tus neeg siv khoom zoo, tso cai rau ob tus kws tshaj lij thiab cov neeg nyiam ua kom tau txais txiaj ntsig zoo nrog kev yooj yim.

3.Faster Surface Enhancement:

Lub teb los yog oscillating motions ntawm polishers pab kom sai thiab ntau npaum li cas nto, txuag lub sij hawm tseem ceeb nyob rau hauv kev sib piv rau cov tsoos tes polishing.

C.Cov txiaj ntsig ntev rau qhov chaw

1. Kev khaws cia saum npoo:

Kev siv cov polisher tsis tu ncua nrog cov polishes tsim nyog thiab sealants pab khaws cov kev ncaj ncees ntawm qhov chaw, tiv thaiv kev puas tsuaj los ntawm ib puag ncig.

2.Kev Tiv Thaiv Tiv Thaiv Kab Mob:

Polishers pab txhawb kev tshem tawm cov kab mob, xws li oxidation thiab embedded av, tiv thaiv qhov chaw los ntawm kev puas tsuaj mus sij hawm ntev.

3.Extended Surface Lifespan:

Los ntawm kev hais txog qhov tsis zoo thiab siv cov khoom siv tiv thaiv, polishers pab txhawb nqa lub neej ntawm qhov chaw, txawm tias nws yog xim tsheb, rooj tog, lossis lwm yam khoom siv.

4.Txo Cov Kev Kho Kom Zoo Dua:

Qhov chaw uas tau txais kev saib xyuas polishing yuav tsum tsis tshua muaj kev sib chwv thiab nthuav dav, txo cov kev saib xyuas tag nrho lub sijhawm.

Polishingnyob txawv Kev lag luam

Polishing yog txheej txheem ntau yam uas hla kev lag luam, muab kev hloov pauv mus rau ntau yam khoom thiab qhov chaw.Cia peb tshawb xyuas seb cov txheej txheem tseem ceeb no tau siv li cas hauv cov haujlwm sib txawv:

A. Automotive Detailing

1. Nto Restoration:

Hauv kev nthuav dav tsheb, polishers yog siv los kho thiab txhim kho cov tsos ntawm cov xim tsheb.

Lawv zoo tshem tawm cov cim swirl, khawb, thiab oxidation, rejuvenating cov xim pleev xim.

2. Gloss Enhancement:

Polishers pab txhawb rau kev txhim kho gloss ntawm automotive nto, xa cov chav ua yeeb yam zoo li ua tiav.

Lawv yog cov cuab yeej cuab tam hauv kev ua tiav cov kws tshaj lij, pom kev ci ntsa iab ntawm lub tsheb, maus taus, thiab lwm yam tsheb.

3. Headlight Restoration:

Polishers ua lub luag haujlwm tseem ceeb hauv kev kho lub teeb taub hau los ntawm kev tshem tawm cov nplaim taws thiab khawb, txhim kho kev pom thiab kev nyab xeeb.

4. Hlau thiab Chrome tiav:

Tshaj li cov xim, polishers yog siv rau hlau thiab chrome tiav ntawm ntau yam khoom siv hauv tsheb, kom ntseeg tau tias polished thiab corrosion-resistant nto.

B. Woodworking thiab Furniture

1. Ntoo nto Smoothing:

Hauv kev ua haujlwm ntoo, polishers pab txhawb kom smoothing ntoo nto, tshem tawm imperfections thiab txhim kho lub ntuj lis.

2. Stain and Finish Application:

Polishers pab nyob rau hauv daim ntawv thov ntawm cov ntoo stains thiab finishes, kom ntseeg tau tias txawm faib thiab ib tug zoo tsos.

3. Rooj tog Restoration:

Kev kho cov rooj tog qub txeeg qub tes feem ntau yog siv cov polishers los kho thiab khaws cov qub kev zoo nkauj ntawm cov ntoo.

4. Varnish thiab Lacquer Polishing:

Polishers tau ua haujlwm kom ua tiav qhov tsis muaj qhov tsis txaus ntseeg thaum siv cov kua roj vanish lossis lacquer rau cov rooj tog zaum, tsim kom muaj qhov chaw ruaj khov thiab zoo nkauj.

C. Hlau thiab hniav nyiaj hniav kub Polishing

1. Hlau nto tiav:

Hauv kev lag luam metallurgy, polishers yog siv los ua kom tiav thiab polishing hlau, muab qhov zoo nkauj thiab ci ntsa iab.

2. Cov hniav nyiaj hniav kub Polishing:

Cov neeg tsim khoom siv nyiaj txiag siv cov polishers los ua kom zoo dua qub thiab txhim kho qhov ci ntawm cov hlau muaj txiaj ntsig, gemstones, thiab cov ntsiab lus sib txawv.

3. Tshem tawm Oxidation:

Polishers ua lub luag haujlwm tseem ceeb hauv kev tshem tawm oxidation thiab tarnish los ntawm cov hlau nto, kho lawv cov brilliance.

4. Precision Polishing rau Cheebtsam:

Nyob rau hauv precision engineering, polishers yog ua hauj lwm los kho qhov chaw ntawm hlau Cheebtsam, kom ntseeg tau nruj tolerances thiab polished tiav.

Kev kos duab ntawm polishing yog ib qho kev coj ua thoob ntiaj teb nrog kev siv dav dav hauv kev nthuav dav tsheb, ua haujlwm ntoo thiab rooj tog, thiab hlau thiab hniav nyiaj hniav kub polishing.Cov teebmeem kev hloov pauv ntawm polishers pab tsis tau tsuas yog rau kev txhim kho kom zoo nkauj xwb tab sis kuj rau kev khaws cia thiab ntev ntawm qhov chaw thoob plaws ntau yam kev lag luam.Txawm hais tias nws tau coj rov qab ci rau lub tsheb classic, txhim kho kev zoo nkauj ntawm cov rooj tog ntoo, lossis kho kom zoo nkauj ntawm cov hniav nyiaj hniav kub, polishers ua lub luag haujlwm tseem ceeb hauv kev ua tiav kev ua tau zoo thoob plaws ntau qhov chaw.

Polishing vs. Waxing

Polishing thiab waxing yog cov kauj ruam tseem ceeb hauv kev saib xyuas saum npoo, txhua qhov ua haujlwm sib txawv hauv kev ua kom tiav qhov tsis zoo.Cia peb delve rau hauv qhov sib txawv, thaum twg yuav ntiav txhua tus txheej txheem, thiab yuav ua li cas sib txuas lawv tuaj yeem ua tiav cov txiaj ntsig zoo:

A. Qhia qhov txawv

1. Polishing:

Lub Hom Phiaj:

Lub hom phiaj tseem ceeb ntawm polishing yog los kho qhov tsis zoo ntawm qhov chaw, xws li khawb, swirl marks, thiab oxidation.

Txheej txheem:

Polishing suav nrog kev siv cov abrasives kom tshem tawm cov txheej nyias ntawm cov khoom siv saum npoo av, ua kom muaj qhov tsis sib xws thiab rov ua kom du, txawm tias ua tiav.

Qhov tshwm sim:

Cov txiaj ntsig ntawm polishing yog qhov ua kom zoo, kho qhov chaw uas nthuav tawm kev txhim kho gloss thiab clarity.

2.Waxing:

Lub Hom Phiaj:

Waxing tsom rau kev tiv thaiv qhov chaw los ntawm kev tsim cov txheej txheem fij tseg uas tiv thaiv ib puag ncig cov ntsiab lus, UV rays, thiab cov kab mob.

Txheej txheem:

Wax yog siv rau ntawm qhov chaw polished, tsim ib qho kev tiv thaiv uas ntxiv qhov tob, ci, thiab dej-beading zog.

Qhov tshwm sim:

Qhov tshwm sim ntawm waxing yog ib qho chaw tiv thaiv zoo nrog ntxiv luster thiab ib qho thaiv tiv thaiv kev puas tsuaj.

B. Thaum twg yuav Polish thiab thaum twg yuav siv quav ciab

1. Thaum Polish:

Surface Imperfections:

Polish thaum qhov chaw muaj qhov tsis zoo xws li khawb, cov cim swirl, lossis oxidation uas xav tau kev kho.

Kev npaj rau kev tiv thaiv:

Ua ntej waxing, raws li polishing npaj qhov chaw rau daim ntawv thov ntawm cov khoom tiv thaiv.

2.Thaum Twg Los:

Tom qab polishing:

Thaum cov nto tau polished thiab imperfections hais, waxing raws li kev tiv thaiv thiab txhim khu lub polished tiav.

Kev tu txhua hnub:

Periodically wax nto kom muaj kev tiv thaiv thiab khaws cov polished tsos.

Daim ntawv thov raws caij nyoog:

Siv cov quav ciab raws caij nyoog los tiv thaiv cov huab cua tshwj xeeb, xws li UV rays, los nag, lossis daus.

C. Kev sib xyaw ua ke kom tau txais txiaj ntsig zoo

1. Kev thov ua ntu zus:

Polish Thawj, Ciab Thib Ob:

Ua raws li txoj hauv kev ua ntu zus kom ntseeg tau tias qhov tsis zoo yog daws los ntawm polishing ua ntej siv cov txheej tiv thaiv ntawm wax.

Txhim kho qhov tob thiab ci ntsa iab:

Kev sib xyaw ua ke ua rau muaj qhov chaw uas tsis yog tsuas yog kho qhov tsis zoo xwb tab sis kuj nthuav tawm qhov tob, ci, thiab kev tiv thaiv.

2. Kev tu tsis tu ncua:

Periodic Waxing:

Ua raws li cov txheej txheem niaj hnub waxing los tswj cov txheej txheem tiv thaiv thiab ua kom ntev polished tiav.

Qee zaus Polishing:

Raws li xav tau, polish qhov saum npoo los daws qhov tsis zoo tshiab lossis tswj qhov xav tau qib ntawm gloss.

3. Xaiv cov khoom tsim nyog:

Compatible Formulas:

Xyuas kom meej tias cov khoom polishing thiab waxing siv tau sib xws kom ua tiav qhov kev pom zoo thiab cov txiaj ntsig.

Cov Khoom Zoo:

Xaiv cov khoom zoo rau ob qho tib si polishing thiab waxing kom ua tau zoo thiab ua haujlwm ntev.

Hauv kev xaus, kev nkag siab qhov sib txawv ntawm polishing thiab waxing yog qhov tseem ceeb rau kev saib xyuas zoo.Paub txog thaum twg yuav polish thiab thaum twg yuav siv quav ciab, thiab siv txoj hauv kev ua ke, tso cai rau lub tswv yim zoo uas hais txog kev kho thiab kev tiv thaiv.Qhov tshwm sim yog ib qho chaw uas tsis tsuas yog zoo li refined thiab glossy tab sis kuj nyiam kev tiv thaiv ntev tiv thaiv cov ntsiab lus.

Khaws Koj Cov Polisher

Kev saib xyuas kom zoo ntawm koj lub polisher yog qhov tseem ceeb los ua kom muaj kev ua haujlwm zoo ib yam thiab txuas ntxiv nws txoj sia.Cia peb tshawb nrhiav cov lus qhia tseem ceeb rau kev ua kom koj cov polisher nyob rau hauv qhov zoo:

A. Cov lus qhia txog kev tu thiab khaws cia

1. Kev Tu Tom Qab Siv:

Tom qab txhua qhov kev siv, ntxuav lub polishing ncoo thiab lwm yam khoom seem ntawm polisher nto.

Siv cov txhuam los yog cov cua compressed kom tshem tawm cov khoom seem ntawm cov khoom sib txawv.

2. Kev tshuaj xyuas Pad:

Tsis tu ncua tshuaj xyuas qhov xwm txheej ntawm polishing pads rau hnav thiab tsim kua muag.

Ntxuav los yog hloov cov ntaub qhwv raws li xav tau los tswj kev polishing zoo.

3. Sab nrauv so-down:

So rau sab nrauv ntawm lub polisher nrog ib daim ntaub ntub dej kom tshem tawm cov plua plav los yog polish residue.

Ua tib zoo saib xyuas qhov chaw cua thiab qhov cua txias kom ntseeg tau tias cov cua ntws zoo.

4. Cia rau hauv ib lub hnab los yog lub hnab:

Khaws cov polisher rau hauv cov ntaub ntawv tshwj xeeb lossis lub hnab los tiv thaiv nws ntawm plua plav, ya raws, thiab kev puas tsuaj.

Xyuas kom qhov chaw cia txias thiab qhuav kom tsis txhob xeb.

5. Kev tswj kav:

Ua kom zoo coil thiab ruaj ntseg rau cov hlua hluav taws xob kom tsis txhob kinks thiab muaj peev xwm puas tsuaj.

Khaws cov hlua kom deb ntawm cov khoom ntse lossis cov khoom hnyav uas tuaj yeem ua rau puas tsuaj.

B. Kev saib xyuas tsis tu ncua

1. Tshawb xyuas Cov Hluav Taws Xob:

Txheeb xyuas cov hlua hluav taws xob kom pom cov cim ntawm fraying, txiav, los yog raug xaim.

Hloov cov hlua uas puas lawm tam sim ntawd kom tsis txhob muaj hluav taws xob txaus ntshai.

2. Fastener Tightening:

Nyob rau tib lub sijhawm, xyuas thiab ceev cov fasteners, bolts, lossis screws ntawm polisher kom ruaj khov thaum ua haujlwm.

3. Hloov Txhuam Txhuam Lub Cev:

Yog tias koj lub polisher muaj cov txhuam txhuam uas hloov tau, saib xyuas lawv cov hnav.

Hloov txhuam raws li kev pom zoo los ntawm cov chaw tsim khoom kom ntseeg tau tias lub cev muaj zog ua haujlwm zoo.

4. Kev tshuaj ntsuam xyuas vaj tse:

Tshawb xyuas lub iav vaj tse kom pom tias muaj roj to lossis puas.

Hais txog tej teeb meem tam sim ntawd kom tsis txhob muaj kev puas tsuaj ntxiv rau cov khoom siv sab hauv.

C. Kev daws teeb meem ntau yam

1. Overheating:

Yog tias polisher overheats, cia nws txias ua ntej rov siv dua.

Tshawb xyuas qhov cua kom zoo thiab xyuas kom meej tias cov pa cua tsis thaiv thaum ua haujlwm.

2. Poob lub zog:

Yog tias tus polisher ntsib qhov poob ntawm lub zog tam sim ntawd, xyuas cov hlua hluav taws xob kom puas.

Xyuas kom muaj lub zog ruaj khov thiab tswj cov teeb meem hluav taws xob.

3. Kev vibrations tsis zoo:

Kev co ntau dhau yuav qhia tau tias muaj teeb meem nrog lub ncoo lossis cov khoom siv sab hauv.

Tshawb xyuas lub ncoo kom sib npaug thiab xyuas seb puas pom kev puas tsuaj.

4. Tsis sib xws Polishing:

Cov polishing tsis sib xws tuaj yeem ua los ntawm cov ntaub qhwv tsis sib xws.

Hloov lossis tig cov ntaub qhwv tsis tu ncua kom ntseeg tau tias cov txiaj ntsig zoo ib yam.

5. Cov suab nrov txawv:

Cov suab nrov txawv txawv tuaj yeem ua teeb meem nrog cov khoom siv sab hauv.

Yog tias ua tsis tau, sab laj nrog cov chaw tsim khoom cov lus qhia lossis nrhiav kev pab cuam.

Los ntawm kev sib txuas cov kev tu, khaws cia, tu, thiab kev daws teeb meem, koj tuaj yeem ua kom muaj kev ua tau zoo thiab ua haujlwm ntev ntawm koj lub polisher.Kev saib xyuas tsis tu ncua rau cov ntsiab lus no ua kom ntseeg tau tias koj cov polisher tseem yog cov cuab yeej txhim khu kev qha rau kev ua tiav qhov tshwj xeeb nto tiav.

Cov neeg siv tshuaj xyuas thiab cov lus pom zoo

Cov neeg siv tshuaj xyuas thiab cov lus pom zoo muab kev nkag siab zoo rau hauv lub ntiaj teb ntawm polishing, muab kev taw qhia ntawm cov khoom, cov txheej txheem, thiab kev nyiam.Cia peb tshawb nrhiav ntau qhov chaw ntawm cov ntaub ntawv:

A. Cov lus teb los ntawm Cov Kws Tshaj Lij

1. Cov Kws Tshaj Lij Tshaj Tawm Txog Kev Pom Zoo:

Nrhiav kev tawm tswv yim los ntawm cov kws tshaj lij uas niaj hnub siv polishers hauv lawv txoj haujlwm.

Platforms zoo li kev nthuav dav cov rooj sab laj, pawg social media, lossis cov vev xaib tshwj xeeb hauv kev lag luam feem ntau muaj kev sib tham uas cov kws tshaj lij qhia lawv cov kev paub thiab cov lus pom zoo.

2. Online Portfolios thiab tshuaj xyuas:

Tshawb nrhiav online portfolios lossis tshuaj xyuas ntawm cov kev pabcuam nthuav dav.

Cov kws tshaj lij feem ntau nthuav qhia lawv txoj haujlwm, qhia txog cov cuab yeej thiab cov txuj ci uas lawv siv.Cov ntawv pov thawj pom no tuaj yeem qhia tau.

3. Cov Txheej Txheem Kev Lag Luam thiab Kev Tshawb Fawb:

Mus koom kev lag luam cov xwm txheej, kev sib tham, lossis kev cob qhia uas cov kws tshaj lij sib sau ua ke.

Kev koom tes nrog cov kws tshaj lij ntawm tus kheej muab lub sijhawm los nug cov lus nug, sau cov lus pom zoo, thiab cov txheej txheem ua pov thawj ua ntej.

B. Nrov Hom thiab Qauv

1. Hom Lub Npe:

Tshawb nrhiav lub koob npe nrov ntawm polishing tshuab hom hauv khw.

Cov khoom lag luam nrog lub koob npe ntev ntev rau kev ua tau zoo thiab kav ntev yog feem ntau cov kev xaiv txhim khu kev qha.

2. Qauv-Specific Reviews:

Nrhiav kev tshuaj xyuas tshwj xeeb rau cov qauv nrov polishing tshuab.

Tshawb xyuas cov platforms, e-lag luam lub vev xaib, thiab cov ntawv tshaj tawm kev lag luam feem ntau qhia cov ncauj lus kom ntxaws txog qhov zoo thiab qhov tsis zoo ntawm cov qauv tshwj xeeb.

3. Consumer Reports and Rating:

Tshawb nrhiav cov neeg siv khoom ceeb toom thiab kev ntsuas rau cov tshuab polishing.

Cov koom haum soj ntsuam ywj pheej lossis cov vev xaib tshuaj xyuas cov neeg siv khoom tuaj yeem muab cov kev ntsuas tsis ncaj ncees ntawm ntau yam qauv raws li cov neeg siv kev paub dhau los.

C. Kev Sib Tham Hauv Zej Zog ntawm Polishing Techniques

1. Cov lus qhia ntxaws ntxaws thiab pab pawg:

Koom nrog cov rooj sib tham nthuav dav hauv online thiab cov pab pawg hauv social media nplooj siab rau kev saib xyuas tsheb thiab kev saib xyuas qhov chaw.

Koom nrog kev sib tham nrog cov neeg nyiam thiab cov kws tshaj lij txhawm rau sau cov kev nkag siab rau cov txheej txheem polishing nyiam thiab cov lus pom zoo ntawm cov khoom.

2. YouTube Tutorials thiab Reviews:

Tshawb nrhiav YouTube cov lus qhia thiab tshuaj xyuas los ntawm kev nthuav dav cov neeg nyiam.

Cov ntsiab lus yeeb yaj kiab feem ntau muab kev pom kev pom ntawm cov txheej txheem polishing thiab nthuav qhia cov txiaj ntsig ua tiav nrog cov tshuab tshwj xeeb thiab cov khoom lag luam.

3. Blogs thiab cov khoom:

Nyeem cov blogs thiab cov ntawv los ntawm cov neeg paub txog kev nthuav dav thiab cov kws paub txog kev saib xyuas saum npoo.

Cov kws tshaj lij kev lag luam feem ntau qhia lawv cov kev paub, suav nrog cov txheej txheem polishing nyiam thiab cov lus pom zoo rau cov tshuab thiab cov khoom.

Leveraging cov neeg siv tshuaj xyuas thiab cov lus pom zoo yog ib txoj hauv kev muaj zog los mus rau lub ntiaj teb ntawm polishing.Txawm hais tias nrhiav kev nkag siab los ntawm cov kws tshaj lij, tshawb nrhiav cov npe nrov thiab cov qauv, lossis koom nrog kev sib tham hauv zej zog ntawm cov txheej txheem polishing, cov ntaub ntawv muaj txiaj ntsig muaj los ntawm cov neeg uas muaj kev paub dhau los tuaj yeem coj koj mus rau kev txiav txim siab.Thaum koj pib ntawm koj txoj kev taug kev polishing, xav txog ntau qhov chaw los sau cov kev xav zoo sib xws thiab xaiv raws li koj qhov kev xav tau tshwj xeeb thiab nyiam.

Xaus

Hauv kev xaus, peb qhov kev tshawb fawb ntawm polishing tau nthuav tawm lub zog hloov pauv ntawm polishers thoob plaws ntau yam kev lag luam.Cia peb rov hais dua cov ntsiab lus tseem ceeb, txhawb cov neeg nyeem kom nkag siab txog lub ntiaj teb ntawm polishing, thiab xav txog qhov tseem ceeb ntawm cov cuab yeej muaj ntau yam no.

A. Recap ntawm Cov Ntsiab Lus Tseem Ceeb

1. Polishing vs. Waxing:

Peb dissected qhov sib txawv ntawm polishing thiab waxing, nkag siab txog lawv lub luag haujlwm tshwj xeeb hauv kev ua tiav qhov tsis zoo.

2. Khaws Koj Cov Polisher:

Tshawb nrhiav cov lus qhia tseem ceeb rau kev khaws koj cov polisher kom zoo, los ntawm kev tu thiab khaws cia mus rau kev saib xyuas tsis tu ncua thiab daws teeb meem.

3. Polishing nyob rau hauv txawv Industries:

Tshawb xyuas seb polishers ua lub luag haujlwm tseem ceeb hauv kev nthuav dav tsheb, kev ua haujlwm ntoo, rooj tog zaum, hlau ua haujlwm, thiab cov hniav nyiaj hniav kub polishing.

4. Cov txiaj ntsig ntawm kev siv Polisher:

Tshaj tawm qhov zoo ntawm kev ua tiav kev ua tiav, txuag lub sijhawm thiab kev siv zog, thiab kev ruaj ntseg cov txiaj ntsig ntev rau qhov chaw.

5. Cov neeg siv tshuaj xyuas thiab cov lus pom zoo:

Tshawb nrhiav kev muaj txiaj ntsig los ntawm cov kws tshaj lij, cov npe nrov thiab cov qauv, thiab kev sib tham hauv zej zog ntawm cov txheej txheem polishing.

B. Kev txhawb nqa rau cov neeg nyeem kom tshawb txog Polishing

Nkag mus rau kev taug kev polishing yog ib qho kev caw kom txhawb nqa qhov zoo li thiab ntev ntawm qhov chaw.Txawm hais tias koj yog tus kws tshaj lij, tus neeg nyiam ua haujlwm, lossis ib tus neeg mob siab rau kev tswj hwm cov hniav nyiaj hniav kub, tshawb txog lub ntiaj teb ntawm polishers qhib qhov rooj mus rau qhov tsis muaj qhov kawg.Siv lub tswv yim los sim, kawm, thiab kho koj cov kev txawj ntse, nrhiav kev xyiv fab ntawm kev hloov qhov chaw nrog qhov tseeb.

C. Kev xav kawg ntawm qhov tseem ceeb ntawm Polishers

Nyob rau hauv qhov loj tapestry ntawm kev saib xyuas saum npoo, polishers tawm los ua cov cuab yeej tseem ceeb, kev sib txuas ua ke, kev tiv thaiv, thiab kev txhim kho.Lawv qhov tseem ceeb nyob tsis tau tsuas yog nyob rau hauv kev kho kom zoo nkauj tam sim ntawd tab sis kuj nyob rau hauv kev khaws cia ntawm qhov chaw nyob rau lub sij hawm.Polishers txhawb cov tib neeg rau cov khoom siv tes ua qhov chaw uas qhia txog kev ua tau zoo thiab kev saib xyuas kom meej, ua rau lub ntiaj teb uas ci ntsa iab ua tau raws li qhov tseeb.

Raws li koj venture mus rau hauv lub realm ntawm polishing, nco ntsoov tias txhua qhov dhau ntawm polisher yog stroke ntawm craftsmanship, shaping nto nrog finesse ntawm ib tug artist.puag ncig txoj kev taug kev, siv lub zog ntawm polishers, thiab txaus siab rau qhov txaus siab ntawm qhov pom ntawm qhov chaw hloov pauv hauv qab koj txhais tes txawj.

Post lub sij hawm: Nov-16-2023